Super Turbo Tuareg Rally - new pics

I've been very distracted with work since the beginning of the year which has meant that my SuperTurbo project has largely been on hold save a little work to get the BMW M series gearbox to work with the 606.

That's set to change from 1st Aug and I'll get back on track with the conversion of my W460 in preparation for the Tuareg in March next year.

The working plan hasn't changed a lot with STD OM606 coupled to a BMW GS6 M series gearbox/ Koni Raid HT and Orc suspension.

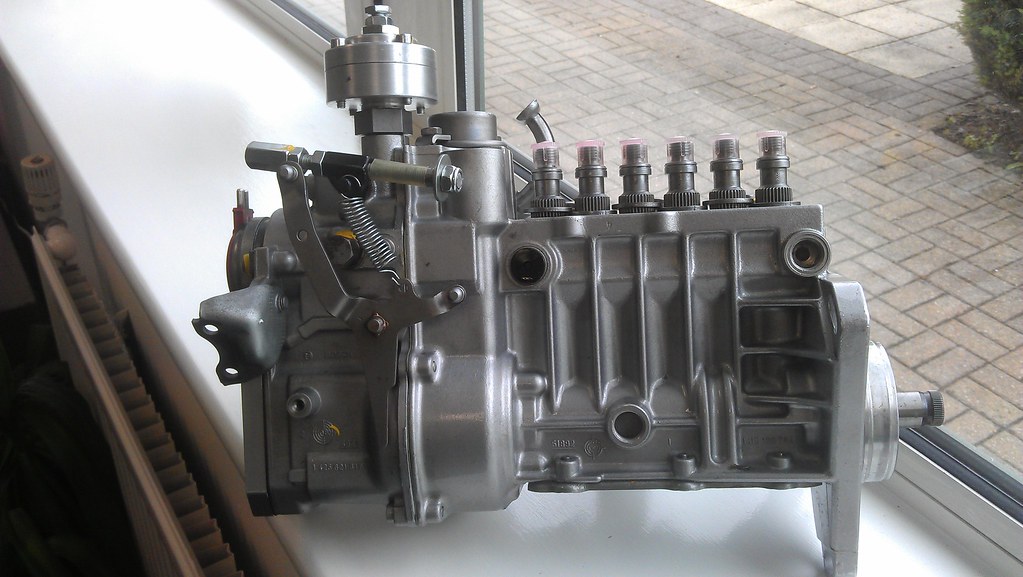

The 606 is to use the STD standard approach with a Myna'd 603 pump (7mm elements) a modified Holset HX35 (35/40 hybrid) turbo /equal length twin scroll (eplit) manifold. Only internal changes are cams, springs and porting of head; pistons rods etc will stay stock. I'm shooting for 450-500HP/ 800NM

I'll keep things updated here for anyone who is interested (bulk of documentation will be on my flicr account though).

First thing to do is order all of the bits I need for the sump swap - Gav you'll have a PM momentarily ;-)

Thought you had fallen off the face of the earth!!!!

How hard to merry OM606 engine with BMW M gearbox ? :)

I have OM605 and thinking to get/send to myna pump and get 8mm elemets with 2bar alda. Turbo with changing rotor angle...

For now I have good 2.7CDI sprinter gearbox what works very good, but with power increase I dunno how my gearbox will cope with it. In hard offrouding, when winching better you have slippery gearbox, not like BMW M drifters.

Thanks for taking time to write about your project!

Ok, technicaly it seems you can merry any engine with gearbox trough bell. How I understand till now MB only has old engines like OM617 and new ones from OM602 till CDI... all two groups works with same starter and can connect to same gearbox. New engines has original bell to connect old gearbox from sprinter.

The problem I see is clutch. Ok, BMW gearbox can take lot of power, I don`t see any problem there, but all use mostly not slippery clutch.

For road and for example drift etc you don`t want that clutch can slip and use like in picture new clutch plate, but in offroad when winching like in picture old clutch plate is better, to help while winching play with clutch that slips... to find traction... :)

Want to understand is there posibility, if you have lot of power to have clutch that can hold normaly power and in the same time to play if needed in offroud with slippery clutch without problems to change too often.

Want maybe after few years to try twin clutch gearbox. But MB seems for now only maded for new SLS version. It can be maybe possible easy to add, but will cost small fotune... :) Only cheapest maybe will be to find from BMW M series and try the same job like you... But I don`t like electric controlers and I converted project w460 to 24 volts for bigger power :)

450-500 bhp is a heck of a lot of power coupled with an enormous amount of torque how will your brakes cope?

Thanks, didn`t know about satch clutch system. Then gearbox bell need to rebuild bigger too, to accommodate two plates?

I`m realy not a mehanic, I was under impresion that this century BMW all has cotrollers in everything is it manual or automatic... :) Haven`t yet researched about those gearboxes at all. You right, it starts to make sense.

About prices, I`m living in oposite side of EU so custome job sometime is not evalutated so high, but it tend to not to be so good and mostly without guarantees.

One of my mechanics what has done some jobs on my car has clients that tryed to put turbo with variable geometry. Said that possible to put mechanical on my car without electric controllers. Did not tell more, want that I will drive to him and spend some money... :) Some said that those are not good mechanical and in hard offroading... some realibility issues. But also some said I will have problems with 24v computer controlled alternator(was easy to access new so I put and find how to work without comuter) and almoust 3 years without problems still.

OM605 is best for me. last possible mechanical, I think. For offroad G OM605 is less weigt, less heat and more room to work arroud!!! :) Don`t see any benefits in Om606 for me and in our country 3 times more expensive.

With 500hp I think in hard offroad other problems will start to emerge, will need to convert to automatic to go easy on axles... 300hp maybe is my goal +/-...

Thinking till november to convert from w460 to w463 axles and thinkig how to convert rear to disc brakes. ORC is not cheap, use parts from sprinter axles. The biggest problems I see is handbrake to make nice to be convincing in our country MOT. We have rumors that our MOT is hardest in all EU :( and I think it is twice hard to upgrade something to be road legal here.

fcp PM! :)

For the GS5-39 series gearboxes which are cheap (couple of hundred £) and popular over on Superturbodiesel, there is no choice but a cut and shut - chopping the bellhousing off one and welding on another.

Depending on how reliable you need it to be, the operation can range from 'good enough for farm work' to a much more precise alignment. Bear in mind though that a runout of more than a couple of tho is going to put pressure and wear on the driveshafts..

The GS5 will handle getting on for 1000Nm.

The GS6-53 which is what I am using is tjhe 6 speed version from the newer BMs and will handle considerably more. The good news here is that the bellhousing - though not the same pattern, is big enough to accomodate a 240mm flywheel (which is what the 606 would use if you do a solid flywheel conversion typically.

Because of this, an adapter plate solution is possible, which has the potential at least to be as acurate as the conventional arrangement - especially if you take the time to use dowels etc for location.

Its not all straightforward because the starter is in the wrong place, and - for my application at least, it will almost certainly require a custom flywheel to accomodate the additional dept. A multi-plate clutch is also probably on the cards as unless you want an un street drivable vehicle then paddle clutches are the only single plate solutio that would hold the torque.

The other downside is the cost. GS6 gearboxes occasionally come up cheap, but be prepared to pay £750 - £1000+ for a low milelage example.

That said for what I'm going to do with it, there isn't a better option. I need something that will be super reliable and robust.

I'm optimistic that this gearbox, coupled with a short shift kit and suitable gearing otherwise (33" tyres) will perform well across the 6 ratios it has.

If you are interested in doing a similar project, I could probably manufacture a run of adapter kits for the 606 and GS6 - I'm not sure whether the bellhousing is the same with the 605 (likely I would say) and I don't know what the kit will run to.